Powerhouse Wind is now a member of ISC – the Infrastructure Sustainability Council – which accredits projects in NZ and Australia for their sustainability. We now have both a member profile, and an ISupply profile on which the PowerCrate is listed . By joining ISC we have passed a first assessment of our product for the construction space, i.e. we have a product that may be important for infrastructure company projects. With our ISupply listing we are now able to socialise PowerCrate within construction project management circles.

When comparing renewable energy generators such as wind turbines and solar panels to the humble diesel generator which one makes more sense?

For remote applications the diesel generator has proven itself to be a marvel of engineering – compact, instant start-up, and diesel is a ubiquitous, high energy density fuel. Solar panels or turbines on the other hand, normally would require significant installation and energy is not ‘on hand’ , but intermittently generated and stored. Diesel generators do have their problems – noise, emissions, and dutiful maintenance requirements – but for pure utility and flexibility they are hard to beat.

However, ‘the times they are a changing’, and if there is a better way of doing something by avoiding carbon emissions it should be considered. Our aim is to provide a sustainable option for supporting remote construction activities.

| Deployment time | 1 wk | 1 mo. | 1 yr |

| Energy /kWh (@14.4kWh/day) | 101 | 432 | 5256 |

| Diesel/kg (@30% eff.) | 28 | 119 | 1453 |

| Emissions/kg CO2e | 89 | 381 | 4634 |

PowerCrate was specifically designed to be an alternative power supply for residential edge-of- grid but it has far greater utility. An example is seen below in one of PowerCrate’s early trials supporting a larger, out-of-the-way, Emrod power ‘beaming’ demonstration. Our set-up was in place for four months as the larger demonstration was planned and built, with the PowerCrate providing energy for all office functions inside the ‘white tent’. This avoided running diesel systems until the final demonstration.

Another example of remote construction is building on bare or vacant lifestyle blocks (see image below). In such cases, where grid connections are too expensive or impracticable, a PowerCrate is a cost effective permanent power solution but with additional utility. It can be deployed early-on to support the construction of the house, but then remain permanently as the off-grid power solution. In one such example in South Canterbury, the PowerCrate supports the initial build after which its energy management system will be further integrated to roof-top solar panels for a complete off-grid power solution.

In fact, the PowerCrate overcomes many of the shortcomings of renewable energy systems in construction projects:

Modular and portable: The PowerCrate has been devised with transportability in mind. It is built into a 20ft container-size frame and at 3 tonne it is compatible with typical freight handling machinery including HIABs and forklifts.

Immediate power: In a vast improvement to typical renewable energy installations PowerCrate deploys in about 2 hours. Panels are folded out and turbine is folded up (see demo here). We do all the assembly and testing back at the factory, so that the final module is ‘plug and play’. The PowerCrate includes a small 6kVA or 9kVA generator with a 28L fuel tank to top up batteries in the worst of weather (overcast and still). The energy stored in our 28kWh battery would be the equivalent of about 7.5kg (9L at a generator efficiency of ~30%). So, the PowerCrate on delivery has 37L equivalent of fuel comparing with 10kVA diesel generator tanks from 60-100L. But of course, the PowerCrate is harvesting and storing its own energy as you are using it. The point is that 2 hours after deployment the PowerCrate will supply 10kVA single phase or 15kVA three-phase as needed.

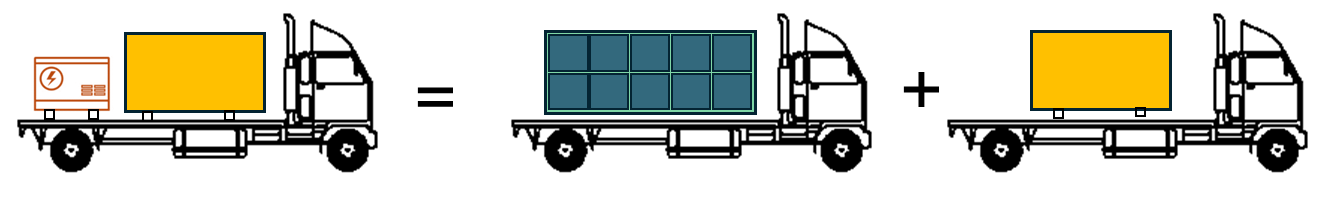

Power Density: With the solar panels and turbine inside the same foot print we offer the highest energy density (in kW/m2) renewable generator. But hands-down the diesel generator will beat the PowerCrate when considering pure power delivery in kVA/kg or kVA/m3. This raises a fair question regarding emissions claims – if one has to carry a 3 tonne PowerCrate in place of a 700kg 10kVA generator, what are the emissions savings? Or put anther way, what is the minimum time we have to use it on site before we are winning?

The answer depends on the truck sizes and the amount of equipment that needs to be transported for a particular project. If a single tuck is carrying the generators (PowerCrate or diesel generator) and still has space for the rest of the cargo then you will be winning from day one. If, however, we consider a worst case scenario where smaller 7T trucks are being used, then because of its low power density (kVA/m3), a PowerCrate will essentially fill the truck bed. A 700kg 10kVA generator on the other hand, leaves ample space for other cargo. In this case then, you may need at most one extra return trip for a 7T truck. How long would the PowerCrate need to be used to off-set the emissions for the carbon emission from this extra trip?

To get a quantitative answer we can compare the difference in emissions for two cases:

Case 1) A single truck, carrying a 700kg diesel generator with the rest of its carrying capacity used for ‘other equipment’

Case 2) Two trucks, one carrying the PowerCrate only, and the second truck carrying the ‘other equipment’

In both cases, a fully laden return journey is considered. For the calculation, make the following assumptions*:

- A tare weight of a four-wheel curtain sider of 5890kg

- A maximum carrying capacity of 5110kg and a load factor of 80%

This leads to the ‘other equipment’ in this example weighing 4410 kg. A very good estimate of the fuel efficiency (FE) of diesel trucks based on the gross vehicle mass (GVM) is:

FE = 0.0016 x GVM + 7.89

where FE is in the unit of litres of diesel/100km and the GVM has the unit of kilogram**. If one proceeds through the calculation, a good estimate is that the PowerCrate has to be on site 9 days for every 200 km total carriage (i.e there and back).

In summary, Powerhouse Wind has developed a sustainable energy solution that also aids remote construction. Our product cannot replace all diesel generators onsite , however they make perfect sense in a growing number of applications on remote constructions sites such as compound offices, and battery charging for tools and topping up EV vehicle charge. As a greater number of light construction vehicles become electrified, Powerhouse Wind will be there, continuing to increase generation, battery capacity, and power delivery.

*https://craneandcartage.co.nz/vehicle-specs/

**Haobo Wang, Iain McGlinchy and Ralph Samuelson,” Real-world fuel economy of heavy trucks” Transport Knowledge Conference 2019. https://www.knowledgehub.transport.govt.nz/assets/TKH-Uploads/TKC-2019/Real-world-fuel-economy-of-heavy-trucks.pdf

Recent Comments